Wbs Work Breakdown Structure

A Work Breakdown Structure (WBS) provides a hierarchical or a breakdown structure that decomposes the project scope into more discrete and manageable work components [1]. The process of breaking down the scope into a WBS should continue until the entire project scope is decomposed in adequate details matching the level of control that the project team wants to exercise.

A fixture in classic project management methodology and systems engineering, the work breakdown structure (WBS) is a method that breaks a project down into a hierarchy of deliverables, tasks, and subtasks. It’s a helpful tool that defines a detailed cost or time estimate and provides guidance for schedule development and control.

WBS breaks down the entire project scope into meaningful components. WBS is a key project artifact that provides a basis for project planning, performance measurement, and project control. It also creates common language among the project team members and stakeholders to ensure everyone is using the same terms in referring to specific parts of the project scope.

Contrary to the popular belief that only one WBS should be developed for each project, it is suggested that two WBSs be produced to define a project scope: a deliverable-oriented WBS and a process-oriented WBS [2,3]. These two work breakdown structures are different but they are not produced independently of each other. Developing and using these two key types of WBS has certain benefits that justify the efforts to produce these two artifacts and use them in tandem.

A deliverable-oriented WBS (also known as product-oriented WBS) decomposes the project scope into smaller and more manageable deliverables. Deliverable are tangible components that need to be delivered to complete the project. They are typically a physical component or an item that needs to be produced, obtained, or supplied as a result of executing project activities. These deliverables are either interim or ultimate deliverables that are delivered to satisfy project requirements. In construction projects, preliminary plans and specifications, bid documents, and pre-construction mockups are example interim project deliverables. Example of ultimate project deliverables in a construction project may include concrete structures, structural steels, building facade, and a building’s mechanical system.

WBS elements in a deliverable-oriented WBS are typically in the form of a noun because WBS elements identify tangible components that are typically a physical item that needs to be produced, obtained, or supplied. A verity of breakdown criteria can be used to develop a deliverable-oriented WBS to meets the specific needs of projects. For example, a construction contractor may breakdown its scope of work based primarily on physical locations of different project components; whereas, a mechanical contractor may use a system-wise approach to identify systems, sub-systems, and lower level components in each subsystem to decomposes its scope of work. The following figure provides an example deliverable-oriented WBS for a residential project.

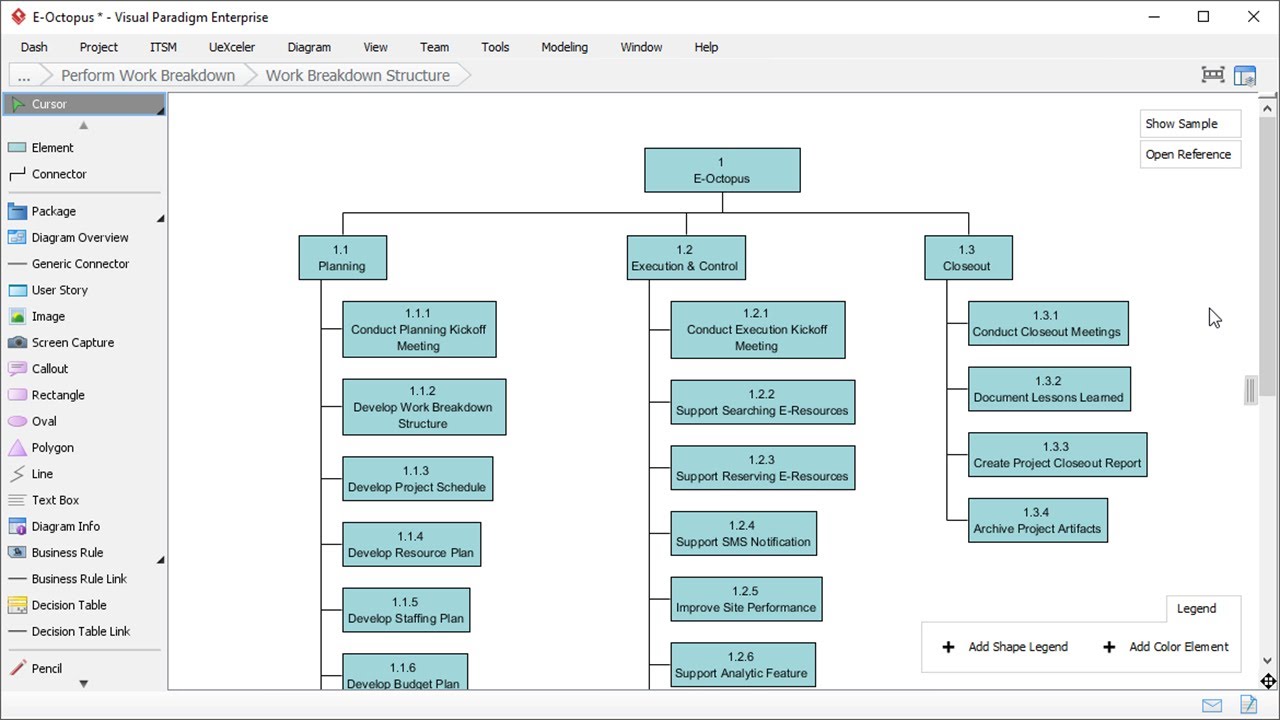

A process-oriented WBS, on the other hand, defines the project scope of work in terms of process steps (i.e., work phases, or functions)[5]. A process-oriented WBS defines what process steps need to be taken to deliver each of the project deliverables. WBS elements in a process-oriented WBS are typically in the form of a verb. They may also identify different work disciplines that are involved to work on various project deliverables. Example WBS elements in a process-oriented WBS include engineering, detailed design, procure, install, and construct. These WBS elements are provided in a hierarchical structure to breakdown the project scope into different functions or process steps. For example, a WBS element such as install may need to be broken down into mechanical and electrical installation depending on a particular project’s scope of work and the scope of responsibilities of the party that is developing the WBS. The following figure provides an example process-oriented WBS for a piping project.

It is important to properly develop project work breakdown structures by choosing proper breakdown criteria, selecting meaningful WBS elements, and using proper level of breakdown to ensure a) project deliverables are properly identified and organized in a hierarchical structure b) work processes are identified in an appropriate fashion to ensure project team members have the same understanding of what needs to be done from a work process or functional perspective to deliver each project deliverable. Developing both deliverable-oriented and a process-oriented WBSs also helps project teams to better identify project activities. Spotify web player log in page now.

To learn more about project work breakdown structures and the way project management professionals can use the full potential of work breakdown structures, please contact us.

References:

[1]. Project Management Institute. (2013). A guide to the project management body of knowledge (PMBOK guide). Newtown Square, PA: Project Management Institute. ISBN: 9781935589679

[2]. Golpayegani, S. A. H., & Emamizadeh, B. (2007). Designing work breakdown structures using modular neural networks. Decision Support Systems, 44(1), 202-222.

[3]. AACE International®. RP 33R-15 Developing the Project Work Breakdown Structure, AACE International®, Morgantown, WV, USA

—

Our posts to the Insights page share fresh insights and seasoned advice about many project and construction management topics. To have the Insights monthly newsletter delivered automatically to your email inbox, please subscribe here.

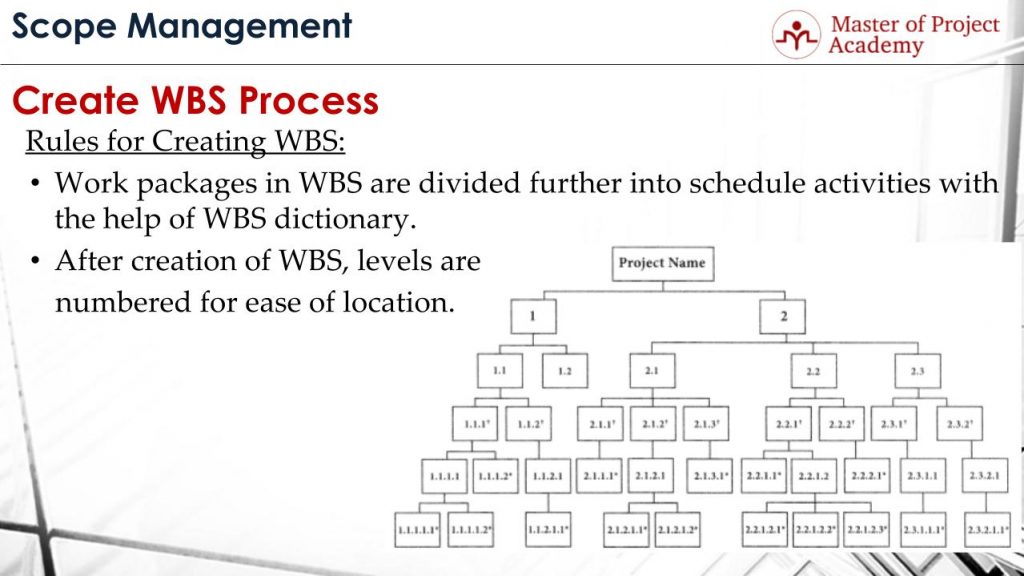

Working on a project WBSA work-breakdown structure ( WBS) in and, is a -oriented breakdown of a project into smaller components. A work breakdown structure is a key project deliverable that organizes the team's into manageable sections. The (PMBOK 5) defines the work-breakdown structure 'A hierarchical decomposition of the total of work to be carried out by the to accomplish the project objectives and create the required deliverables.'

A work-breakdown structure element may be a, or any combination thereof. A WBS also provides the necessary framework for detailed cost estimating and control along with providing guidance for development and control. Contents.Overview WBS is a hierarchical and incremental decomposition of the project into phases, deliverables and work packages. It is a, which shows a subdivision of effort required to achieve an objective; for example a,. In a project or contract, the WBS is developed by starting with the end objective and successively subdividing it into manageable components in terms of size, duration, and responsibility (e.g., systems, subsystems, components, subtasks, and work packages) which include all steps necessary to achieve the objective. Example of work breakdown structure applied in a NASA reporting structure.The work breakdown structure provides a common framework for the natural development of the overall planning and control of a contract and is the basis for dividing work into definable increments from which the can be developed and technical, schedule, cost, and labor hour reporting can be established.A work breakdown structure permits summing of subordinate costs for tasks, materials, etc., into their successively higher level 'parent' tasks, materials, etc. For each element of the work breakdown structure, a description of the task to be performed is generated.

Clicking ribs painful. Stop smoking to prevent coughing and infection. Don’t lift heavy objects or play sports.While most broken ribs heal on their own over time, you should still seek medical attention to avoid complications. Keep your ribcage free from anything that can constrict your breathing, such as bandages or tight clothes. Especially if you have difficulty or pain while breathing. For a Proper Broken Rib Diagnosis, Request an Appointment at The Orthopedic Clinic TodayThe complications involved with a broken rib can be serious.

This technique (sometimes called a system breakdown structure ) is used to define and organize the total of a.The WBS is organized around the primary products of the project (or planned outcomes) instead of the work needed to produce the products (planned actions). Since the planned outcomes are the desired ends of the project, they form a relatively stable set of categories in which the costs of the planned actions needed to achieve them can be collected. A well-designed WBS makes it easy to assign each project activity to one and only one terminal element of the WBS. In addition to its function in cost accounting, the WBS also helps map requirements from one level of system specification to another, for example, a cross reference matrix mapping functional requirements to high level or low level design documents.The WBS may be displayed horizontally in form, or vertically as a tree structure (like an organization chart).The development of the WBS normally occurs at the start of a project and precedes detailed project and task planning.History The concept of work breakdown structure developed with the (PERT) by the (DoD).

PERT was introduced by the U.S. Navy in 1957 to support the development of its missile program. While the term 'work breakdown structure' was not used, this first implementation of PERT did organize the tasks into product-oriented categories.By June 1962, DoD, and the aerospace industry published a document for the PERT/COST system which described the WBS approach. This guide was endorsed by the Secretary of Defense for adoption by all services. In 1968, the DoD issued 'Work Breakdown Structures for Defense Materiel Items' (MIL-STD-881), a requiring the use of work breakdown structures across the DoD.The document has been revised several times, most recently in 2018. The current version of this document can be found in 'Work Breakdown Structures for Defense Material Items' (MIL-STD-881D). The WBS construction technique employing the 100% rule during WBS construction.The figure on the left shows a work breakdown structure construction technique that demonstrates the 100% rule and the 'progressive elaboration' technique.

At WBS Level 1 it shows 100 units of work as the total scope of a project to design and build a custom bicycle. At WBS Level 2, the 100 units are divided into seven elements.

The number of units allocated to each element of work can be based on effort or cost; it is not an estimate of task duration.The three largest elements of WBS Level 2 are further subdivided at Level 3. The two largest elements at Level 3 each represent only 17% of the total scope of the project. These larger elements could be further subdivided using the progressive elaboration technique described above.WBS design can be supported by software (e.g. A ) to allow automatic rolling up of point values. Estimates of effort or cost can be developed through discussions among project team members.

This collaborative technique builds greater insight into scope definitions, underlying assumptions, and consensus regarding the level of granularity required to manage the projects.See also.References. 2006-02-11 at the Defense Acquisition University Press, 2001. Defense Acquisition University. Retrieved 19 September 2017. Booz, Allen & Hamilton, science.energy.gov. Dec 2011.

^ NASA (2001). NASA NPR 9501.2D. May 23, 2001.

Electronic Industries Alliance Standard Systems Engineering Capability Model EIA-731.1. Institute of Electrical and Electronics Engineers Standard for Application and Management of the Systems Engineering Process IEEE Std 1220-2005. Haugan, Gregory T., Effective Work Breakdown Structures, pp7-8. DOD and NASA Guide, PERT/COST System Design, June 1962. Hamilton, R. L., June 1964.

MIL-STD-881, 1 November 1968. MIL-STD-881D, 9 April 2018. Haugan, Gregory T., The Work Breakdown Structure in Government Contracting, Management Concepts, 2003. Effective Work Breakdown Structures By Gregory T. Haugan, Published by Management Concepts, 2001, p.17. Practice Standard for Work Breakdown Structures (Second Edition), published by the, page 8. Swiderski, Mark A., PMP, PMBOK-Work Breakdown Structures.

June 2013. Levy, Lacie, Your Quick Start Guide to Work Breakdown Structure. November 2019. MIL-STD-881C, Work Breakdown Structures for Defense Materiel Items, 3 October 2011, ¶4.3.

Ashe, Kenneth, Accessed 23.